The modern pressroom has high demands: precision, cleanliness, efficiency and sustainability. Daetwyler SwissTec offers a portfolio of accessories for gravure and flexographic printing that is functionally coordinated. Whether it's the reliable sealing of the doctor blade chamber with MDC ENDSEALS, the safe and efficient handling with the MDC PRECUT technology, or the sustainable packaging concept of the MDC DOCTOR BLADE BOX, used in all orders. The system is complemented by our MDC CLEANER, which is used to clean cylinders and print stations. The MDC products are precisely matched to each other. This ensures smooth processes and consistently high print quality.

New standards in precision and work safety

The innovative and worldwide patented MDC PRECUT technology enables the doctor blade to be perforated to the customer's size with millimetre precision – tailored to the respective printing press. Thanks to ultramodern laser technology, the doctor blade can be bent exactly to the desired length. This not only increases precision during use, but also occupational safety throughout the entire process. This technology is applied to all doctor blades and delivered as roll goods. With MDC PRECUT, manual cutting and the associated risk of injury at the doctor blade table are eliminated.

MDC PRECUT

Time-saving and user-friendly

The new solution is based on the usual 100-metre roll – packaging and handling remain unchanged. The difference lies in the details: the doctor blades are pre-perforated to the desired length. A simple bend is all it takes – time-consuming manual cutting is completely eliminated. This saves valuable time and increases safety for employees. In addition, the precise laser process does not create a sharp edge – for clean and safe work right from the start.

Smart packaging

The transparent lid of the packaging always allows a clear view of the remaining doctor blade quantity – for effortless and prompt reorders. Thanks to the integrated predetermined breaking point, the box also protects against manipulation: Once opened, it is clearly visible that the goods are original. The doctor blade box also scores points in terms of sustainability - due to the reduced use of materials, it is lighter and more resource-saving.

MDC BOX

Efficient handling – down to the last meter

The design prevents the doctor blade roll from being pulled back. When used in an upright position, the roll can be unwound cleanly until the very end. The linked video shows the correct use of the MDC Box in a few clear steps – simple yet effective.

Endseal solutions for flexographic printing

MDC endseals reliably seal the doctor blade chamber in flexographic printing and prevent ink from escaping. In combination with the MDC doctor blade, a perfectly coordinated system is created that ensures clean and stable printing processes. The durable materials and precise fit minimize cleaning effort, extend service life and actively contribute to process reliability.

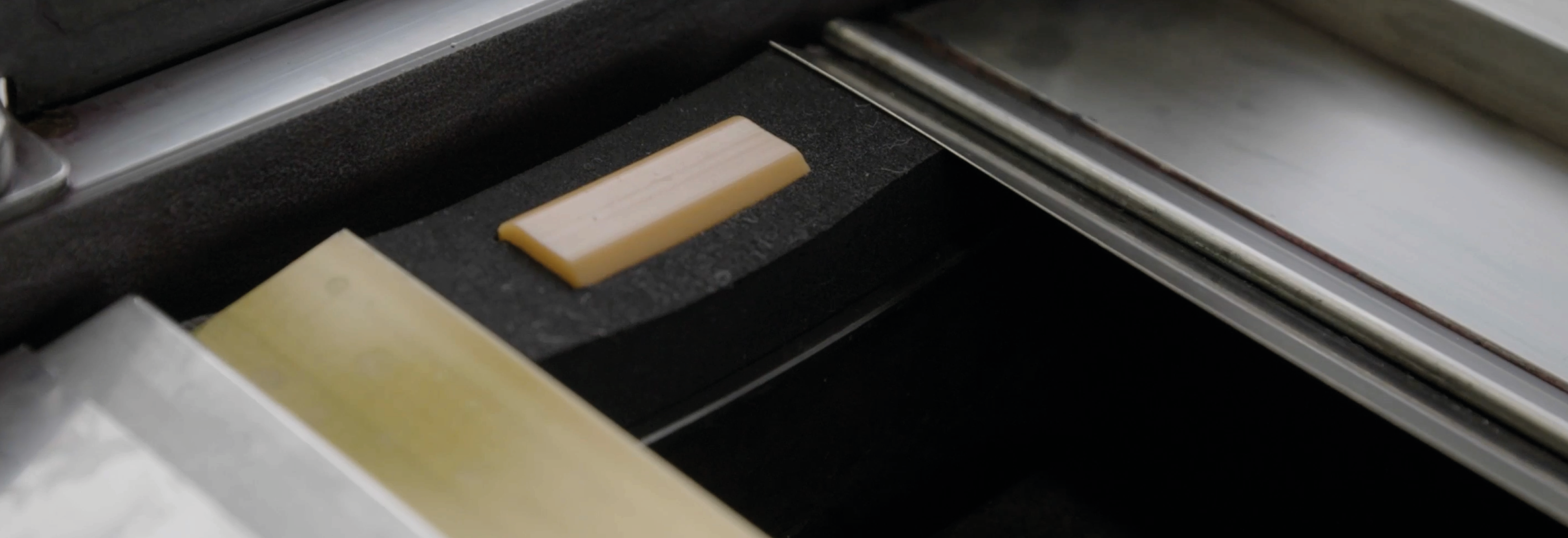

MDC ENDSEALS

The endseals jungle ends here

The endseals in the doctor blade chamber system, just like the doctor blades, are wear parts. The collaboration between both components is decisive for the constant and clean ink transfer during the entire printing process. It is for that reason that Daetwyler SwissTec offers the same run times for the MDC doctor blades and MDC endseals. The products MDC REGULAR, MDC ADVANCED, MDC ADVANCED PRO and MDC EXPERT - allow for a clear overview of the endseal market, which has been flooded with endseal copies, helping you stand out as a clear winner.

The clean solution for your ceramic and chrome rollers

The MDC CLEANER range consists of two cleaning solutions for effective and gentle cleaning of ceramic and chrome rollers: MDC ANILOX CLEANER and MDC AQUA PURE CLEANER. Both remove dirt from all common ink residues, reduce machine downtime and are suitable for use in food printing. Depending on the requirements, a classic as well as a water-based, more sustainable solution are available.

MDC ANILOX CLEANER

Cleaner without VOC emissions

The MDC ANILOX CLEANER is the ideal choice for those looking for effective, fast-acting cleaning without VOC emissions. It is suitable for all types of paints and varnishes, does not cause foaming when washing off and is particularly easy to use. The cleaner comes in a 1-litre bottle and is perfect for use in flexographic and gravure printing.

MDC AQUA PURE CLEANER

Water-based cleaning solution

The MDC AQUA PURE CLEANER is a water-based solution with environmentally friendly properties. Thanks to its biodegradable surfactants, it offers a thorough deep cleaning, also for ceramic and chrome rollers. Additionally, this cleaner is food-safe and reliably reduces machine downtimes. Available in a 1-liter bottle.