The correct choice for the perfect print result

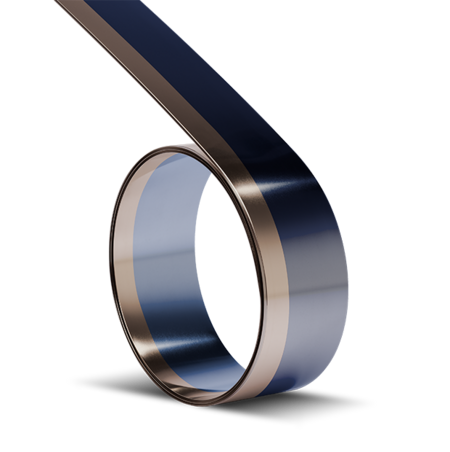

In gravure printing, the printing ink is transferred from recessed ink cavities on the print cylinder onto the print media. The doctor blade plays a major role when wiping off any excess ink. The collaboration between the individual parameters, such as ink, substrate, viscosity, etc., requires an optimized doctor blade in order to achieve the desired print quality. Daetwyler SwissTec offers an all-encompassing portfolio of MDC doctor blades for gravure printing.

-

APPLICATION

What sort of application do you need the MDC doctor blades for?

-

material

Welches Material bedrucken Sie?

-

farben

Mit welchen Farben arbeiten Sie?

- matching doctor blades

- Reset

MDC PRECUT

New standards in precision and work safety

The innovative and worldwide patented MDC PRECUT technology enables the doctor blade to be perforated to the customer's size with millimetre precision – tailored to the respective printing press. Thanks to ultramodern laser technology, the doctor blade can be bent exactly to the desired length. This not only increases precision during use, but also occupational safety throughout the entire process. This technology is applied to all doctor blades and delivered as roll goods. With MDC PRECUT, manual cutting and the associated risk of injury at the doctor blade table are eliminated.